- LED Lighting

- Optoelectronic

- Passive Components

- Sensors

- Circuit Breaker

- Signal Technology

- Connectors

- Memory & Storage

- Power Supply

- Thermal Management

-

Hi-Rel

- Bipolar Junction Transistor (BJT)

- Diodes and Rectifiers

- Phototransistors

- Slotted Optical Switches

- Hall Effect Sensors

- IC Photodetectors (logic output)

- IR-LEDs

- MOSFET-Transistors

- Optocouplers

- Reflective Opto Switches

- Power Circuit Breaker

- Thermostats

- Precision switches

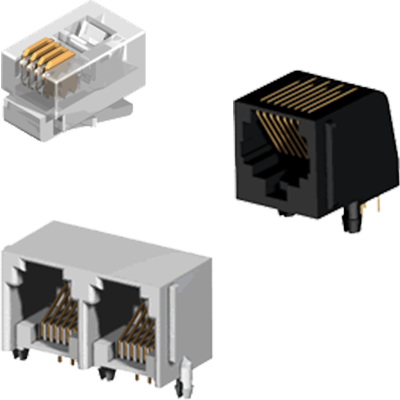

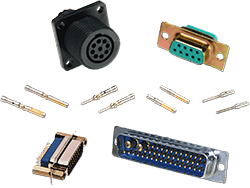

- D-Sub Connectors

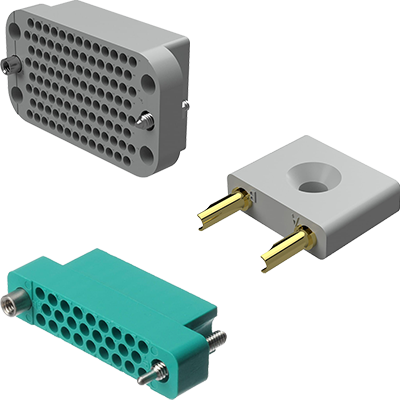

- Leistungssteckverbinder

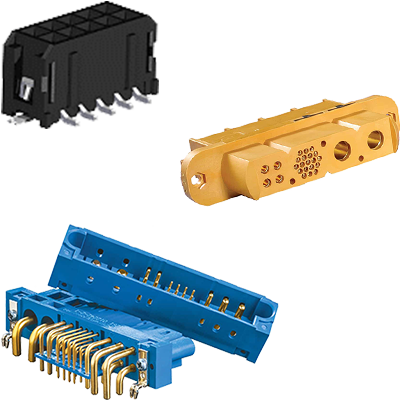

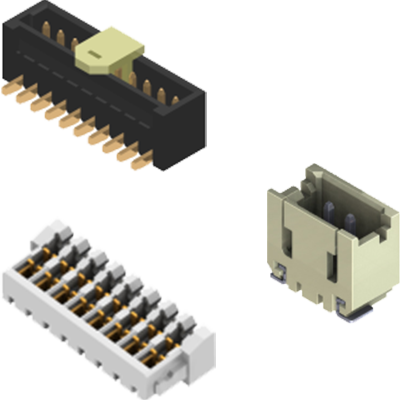

- Rectangular connectors

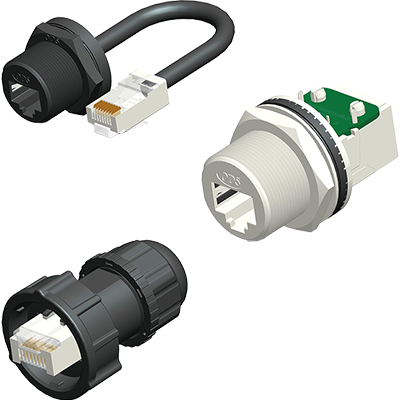

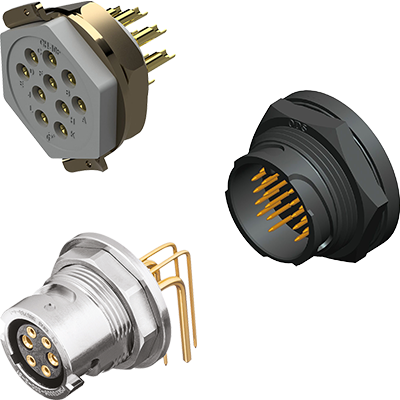

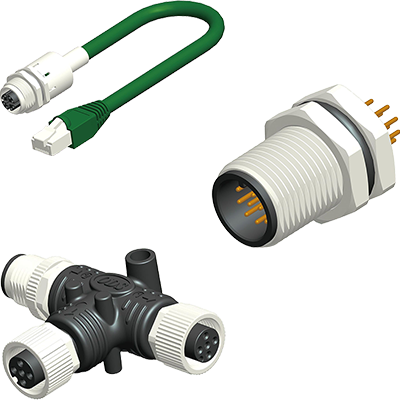

- Round Connectors

- NVMe SSDs

- SATA SSDs

- Cable Assembly

- Diverse

Your search result for:

Please enter at least 3 Characters

Dear interested ladies and gentlemen,

unfortunately we could not find any results for your search.

Please contact us at:

+49 9135 7366665

or write an e-mail to info@neumueller.com

We're here to help.

Your Neumüller Elektronik team

unfortunately we could not find any results for your search.

Please contact us at:

+49 9135 7366665

or write an e-mail to info@neumueller.com

We're here to help.

Your Neumüller Elektronik team