Time-of-Flight (ToF) technology

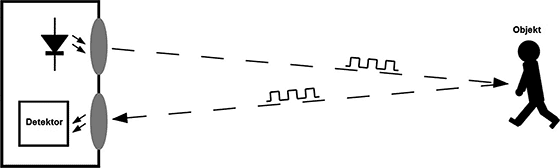

Time-of-Flight (ToF) is a technology that originated in the 1980s. It is based on the pulse transit time measurement of the light. Light is emitted by a transmitter and reflected by one or more objects. The reflected light beams are detected by a receiver and then the distance is determined.

Single or multiple pulse operation

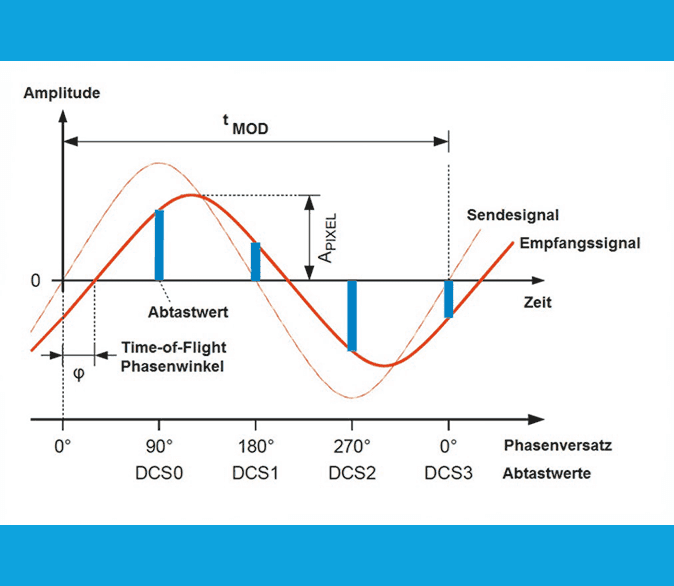

There are basically two types of transit time measurement: single and multiple pulse operation. In single-pulse operation, the time between the emitted and the received individual light pulse is determined. Due to the constancy of the speed of light (about 300 000 km / s), the elapsed time is proportional to the distance. The situation is different in multi-pulse mode: Here, the phase shift between emitted and received modulated light pulses is determined. This also corresponds to a time and is therefore also proportional to the distance.

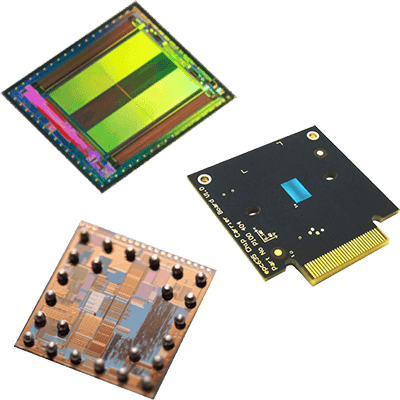

ToF pixel sizes

The structure of a ToF pixel in silicon is significantly more complex than the structure of a pixel of a camera chip. For the special chip technology of ESPROS Photonics AG, ToF pixel sizes of 20 x 20 μm were realized. This results in chip resolutions of up to 320 x 240 pixels (QVGA). With this resolution not only distances can be measured, but also objects or gestures can be detected. This complex implementation tasks can be implemented, such. Device control via gestures, monitoring and intelligent control of elevators and escalators, controls of safety areas around robots and cost-effective implementation of automated guided vehicles. The ToF chips from ESPROS Photonics AG are designed as CSP / BGA (Chip Scale Package / Ball Grid Array) and have a thickness of only approx. 50 μm. This allows much smaller and more compact sensor systems to be developed than was possible in the early days of ToF technology.

Principle of distance measurement

In a ToF system, optics, hardware and software design must work together in an appropriate way. First, the maximum distance to the measurement object must be defined. Multi-pulse operation provides a complete 360 ° phase for maximum, one-way distance. An example: The 360 ° correspond to a maximum distance of 15 m, which means a defined modulation frequency (1 / tMOD). The ToF chip provides 4 samples, so-called DCSx, which are each advanced by 90 ° phases. From these samples, both the amplitude (signal quality) and the distance can be calculated. The output of the 4 DCSx values is done for each of the pixels. Distances can be determined unambiguously up to 15 m. However, if the object is at a distance of 16 m, the ToF system can not unambiguously determine the distance and indicates a distance of 1 m = 16 m - 15 m.

Light amount

Another aspect is the field of view (FOV) of the ToF camera system. In general, the sensitivity of the ToF chip is not the critical size, but rather the amount of emitted light. The transmitter module must provide sufficient light for reflection in the receiver. The following applies: The greater the distance and the field of view, the greater the amount of light that is necessary for the detection of the object. Since it is an optically measuring system, the laser class must also be taken into account when persons can enter the field of view of the camera system.

Influencing variables of the test object

Naturally, the quality, reflectance and speed of the object also influence the measurement result. There are strong and weakly reflective materials. If the light from the object is reflected too weak, this can be difficult or impossible to detect. This must be taken into account in the design phase through appropriately selected integration times. A high speed of movement of the object requires a sufficiently high computing power or the choice of a suitable controller, which processes the measured values sufficiently fast and delivers meaningful results. Recordings of slow or static objects are much easier to process.

Interference

For example, if ToF systems are used inside a building, environmental factors need not be considered. In outdoor use, however, appropriate measures must be taken in hardware and software. Strong sunlight can be suppressed by integrated "Ambient Light Suppression" at the chip level. On the other hand, the measured values for temperature changes must be corrected by means of suitable software routines, depending on the accuracy requirements. Often it is sufficient to work with a higher integration of measured values and to use corresponding correction factors for temperature compensation.

Videos about ToF

Time-of-flight application areas

![Automotive]()

Automotive

![Transportation]()

Transportation

![People counting]()

People counting

![Object recognition]()

Object recognition

![Control]()

Control

![Security]()

Security

![Automation]()

Automation

![Medicine]()

Medicine

![Household]()

Household

![HCI]()

HCI

![Measuring technology]()

Measuring technology

![Many more]()

Many more

Automotive

Automotive

Transportation

Transportation

People counting

People counting

Object recognition

Object recognition

Control

Control

Security

Security

Automation

Automation

Medicine

Medicine

Household

Household

HCI

HCI

Measuring technology

Measuring technology

Many more

Many more